CNC Chamfering – The Secret to a Perfect and Professional Finish

Shari

What is chamfering and why is it essential in CNC machining?

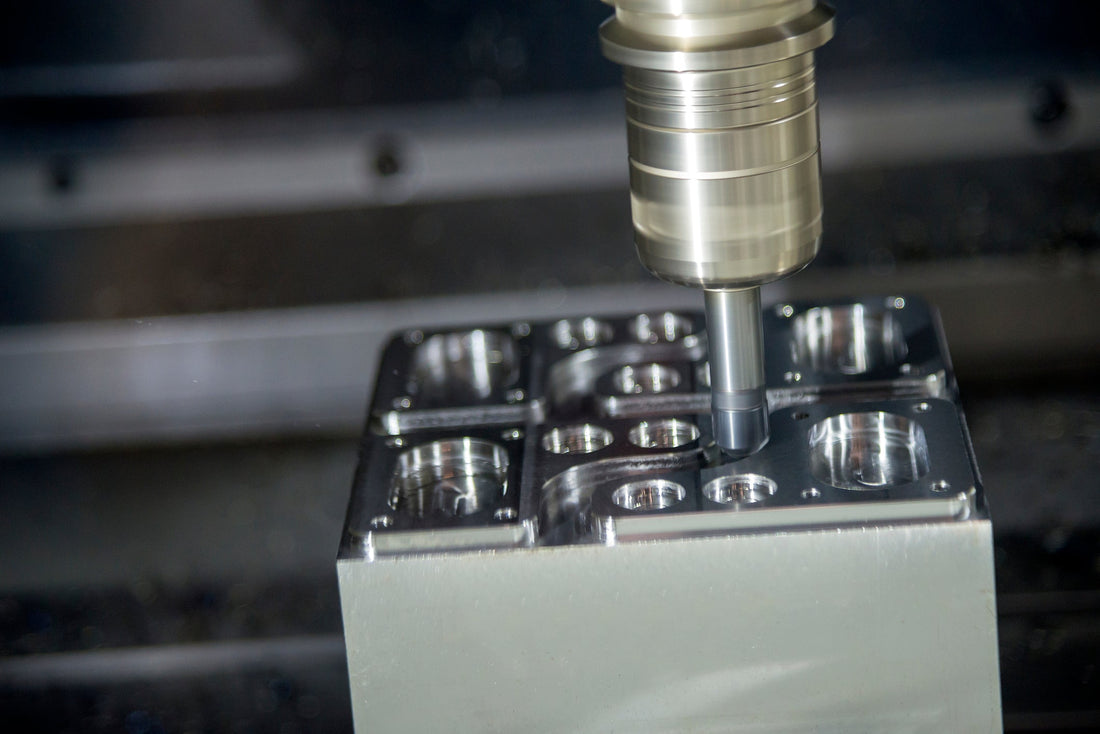

Chamfering is an essential process in CNC machining, used to remove sharp edges and create smooth transitions between surfaces. This process not only improves the aesthetic appearance of the part, but also has a direct impact on the functionality, safety, and quality of the final product.

In industrial processing, raw parts may have sharp edges , which can cause:

✔ Increased risk of injury during handling and assembly.

✔ Difficulty in ensuring precise fit in mechanical assemblies.

✔ Problems in layering coatings (painting, anodizing, etc.).

Through CNC chamfering , we eliminate these problems and guarantee a professional finish, tailored to each client's requirements.

Advanced CNC Chamfering Techniques – Micron-Level Precision

At NEDTRIX , we use advanced CNC technologies to make precise chamfers on all types of materials, whether it's steel, stainless steel, aluminum or engineering plastics .

✔ Chamfering close to walls and corners – no collisions

One of the biggest obstacles in the chamfering process is achieving the finish close to the walls or corners of the part . If the tool is not controlled correctly, it can come into contact with the side walls, compromising the entire machining.

🔹 How do we avoid collisions?

By using an optimal 45° retraction angle , the tool leaves the surface without hitting the part wall, thus ensuring a uniform finish and protecting the tool from premature wear.

🔹 Benefits:

✔ Maximum precision – perfectly controlled tolerances for each edge.

✔ Extended tool life – preventing direct impact increases the longevity of the cutters used.

✔ High efficiency – eliminating sharp edges without the need for additional post-processing.

The Benefits of CNC Chamfering – A Detail That Makes the Difference

A flawlessly machined part does not only mean respecting dimensions and tolerances, but also paying attention to finishes . That is why, at NEDTRIX , we treat each part with the same level of precision and professionalism.

✔ Increased safety – eliminating sharp edges reduces the risk of cuts or scratches during handling.

✔ Premium appearance – CNC chamfering provides a superior finish, reflecting the quality and professionalism of the production.

✔ Improved functionality – parts with smooth edges fit better in mechanical assemblies.

✔ Cost reduction – by integrating chamfering directly into the CNC process, we eliminate the need for costly manual finishing.

✔ Increased durability – correct finishes reduce the risk of microcracks and improve the material's resistance over time.

NEDTRIX – Your expertise in CNC chamfering and industrial finishing

At NEDTRIX , we combine experience with state-of-the-art CNC technology to provide impeccable finishes and ready-to-use parts. Every detail matters, and the quality of the final product is directly influenced by how edges and surfaces are treated.

📩 Do you need precise and high-quality CNC machining? Contact us now and let's discuss your project!

📞 Phone: +40 (770) 959 853

📧 Email: offce@nedtrix.ro